Preventive Maintenance

Preventive maintenance software

The web version is currently available for a FREE Trial on the site of MaintenanceDirecte.ca

Maintenance Directe is offered in SaaS mode (Software as a service) allows the client to benefit from the solution without having to install, manage and maintain a workstation or server.

Preventive maintenance software

With our preventive maintenance software, you will save money because regular preventive maintenance reduces costs by 15% to 50% of expenses related to the repair of production equipment.

- Easy maintenance software, comprehensive and user friendly (easy to use);

- Management of maintenance schedules;

- Management of work orders (corrective);

- Individual monitoring equipment;

- Maintenance equipment history;

- Monitoring equipment wear: day, km, liter or hours;

- Cost management equipment (parts and labor);

- Parts inventory management and suppliers;

- Maintenance software combined with the inventory module provides the ability to combine pieces to maintenance operations and can allow the company to reduce from 50% to 80% storage of parts connected repairs.

Benefits of the software Maintenance Directe

Advanced and comprehensive tools, it remains easy to use. It is a worthwhile investment to increase the company’s profitability and the reduction of equipment breakdown; This saves money and ensures the safety of employees.

Production

- Increased production (%);

- Improved manufacturing time;

- Maintains quality production.

Dépenses

- Decrease in expenses related to repairs;

- Decreased overtime (mechanic);

- Reduced inventory of spare parts;

- Maintain or reduction of insurance costs;

- Lower costs for CSST.

Equipments

- Reduction of mechanical failure;

- Allows the performance and reliability of equipment and buildings.

- Department maintenance;

- Better organization of work for maintenance employees.

Employees

- Reduced risk of work accidents (CSST);

- mproving the quality of the environment (work environment);

- Better relationship between operators and mechanics.

A well-maintained equipment ensures reduce repair costs, resulting in increased performance, profitability of the company and therefore profits. To do this, Maintenance Directe is a handy, comprehensive and easy to use for the management of preventive maintenance.

If we consider only 3% to 5% of sales of a company dedicated to the maintenance and repair of the machinery, Maintenance Direct software, coupled with the inventory module, turns an indispensable asset since it allows the company to reduce from 15% to 50% of expenses related to reparations.

With the inventory module, the preventive maintenance software provides a full version that allows to identify and connect parts for maintenance operations.

The maintenance of your equipment costs you money? We present a solution to reduce costs, an essential tool to maintain your equipment and infrastructure: preventive maintenance software Maintenance Directe

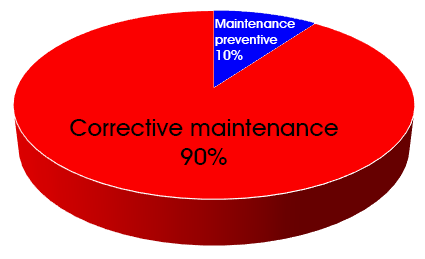

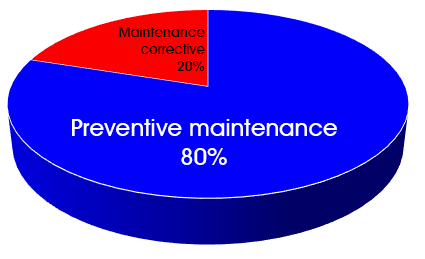

Before

After

Inventory Module Option

The Software Inventory is an add-in Maintenance Directe software. It is used to identify parts, accessories, lubrication products, in short, all the elements necessary for the proper functioning of each machine.

Inventory software manages data to integrate scheduled preventive maintenance. This allows you to hand all the information you need to perform maintenance on your equipment and your work environment.

Indeed, it is even possible to use the software for practical applications as the maintenance of buildings (painting, repairing the roof, replacing fixtures, regular inspection of air conditioning systems, smoke detection, extinguishing fire, etc.).

- Quantity providers: Unlimited

- Amount of inventory parts : 99,999,999

- Suppliers records and preference ranking : yes

- Filtering by combination of keys: Factory / Category / Parts

- Inventory minimum / maximum and prediction parts use

Software specifications of Maintenance Directe

List of reports

- Maintenance Schedule;

- Equipment Sheet;

- Equipment Synopsis;

- List or equipment;

- List of operations;

- List of machine types;

- List of machine operations;

- List of wear operations by machine;

- List of operations per machine including parts;

- Consumer trend (prediction and forecasting of use out of stock);

- Parts List below the minimum;

- List of items in stock (in stock, on order, minimum, maximum and price).

Specifications Data

- Multi businesses : maximum 999

- Multi departments : maximum 999

- Amount of equipment by department: unlimited

- Number of hourly maintenance by equipment: Unlimited

- Number of parts required by maintenance schedule by equipment: Unlimited

- Number of users: Unlimited

- Units of measure wear: Hours and / or Days, Mileage and / or Days

- Quantity operations per database: 98,000 (150 pre-configured)

- The descriptive fields of operations may contain up to 255 characters

- Quantity of machines type by database: unlimited (50 pre-configured)